Energy Recuperation with a Turbo-Generator

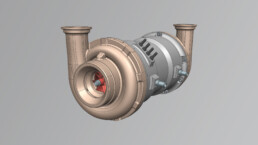

The combination of turbomachine and electric motor as a turbo-generator can be used in a variety of ways for energy recovery. Throttle valves are used in many systems for control purposes, but are associated with high energy losses. A turbine can also provide the throttling effect, and has the advantage of generating shaft power. Throttle energy can thus be recuperated by generating electrical power via a generator coupled to the turbine. This principle is the basis of our ThrottleCharger, which we developed together with Sonceboz for Lambda 1 gasoline engines. The throttling required for load control is efficiently linked to the generation of electrical power.

TurboCool

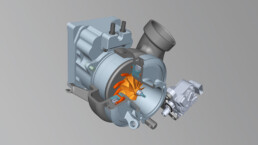

Refrigeration processes are used in many applications, such as in production and storage facilities, vehicle and building air conditioning, as well as in process engineering in general. Conventional refrigerants based on F-gases pose a risk to the environment and safety and will be regulated or prohibited in the future. The time has come for new ideas! With our TurboCool approach, we use air directly as a refrigerant and can provide either cooling and heating output, as the application requires. Based on mass-produced automotive turbocharger components, we have created a demonstrator that illustrates the conceptual elegance of this air conditioning system without needing any F-gases.

Core Competencies

Our expertise lies in how we connect profound turbomachinery knowledge, turbocharged engine system analysis, and well-established methodology.

Learn more

Conceptual Design

Special tasks sometimes require unconventional solutions. We love problems and see them as challenges that stimulate our creativity.

Learn more

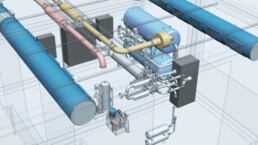

Fuel Cell Air Supply

The overall efficiency of fuel cell systems depends to a large extent on the efficiency of the air supply, which is why turbomachines are increasingly replacing screw compressors. In addition to these efficiency advantages, turbomachines offer the option of converting residual enthalpy by means of a turbine placed at the fuel cell outlet – in other words, energy recuperation. For the thermodynamic evaluation of such air supply systems for fuel cells, we draw on our recognised competencies in measurement technology and conditioning. Therefore, we use test bench systems tailored specifically to this application.